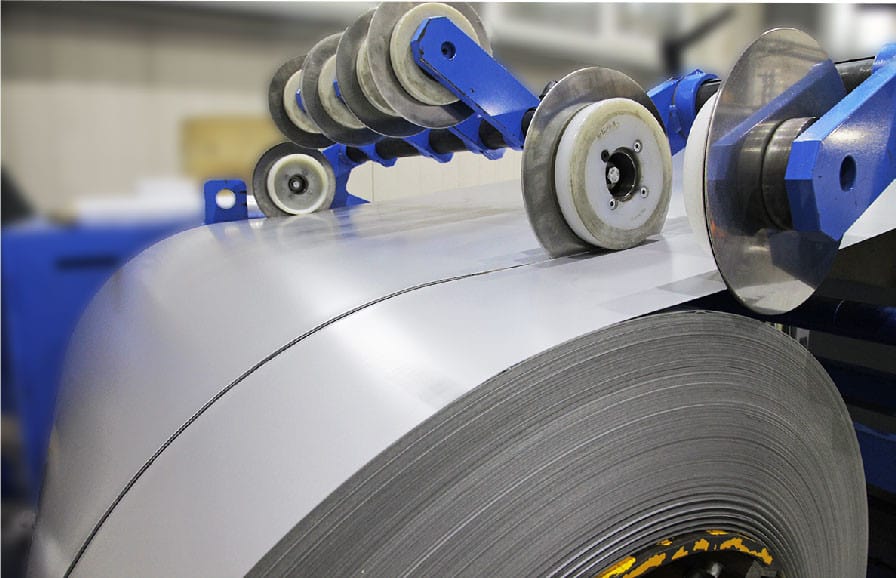

LONGITUDINAL SPLITTING

A mechanical process in which the coiled sheet is cut to length by machines called slitters. Cutting takes place when the sheet metal is unwound and passed through sharpened disc knives, located at a distance from each other depending on the desired widths of the new strips. Which in turn are rolled into new rolls. The strips are guided by distance guides, which provide enough distance so that the new rolls do not touch during rotation. These treatments can be applied to galvanized, polyester, copper, zinc, and aluminum sheets up to 2.00mm thick. The widths of the stripes are in the range of 75 mm up to 1500 mm.