Gutters, together with cisterns and gutters, are the main elements of the roof drainage system. Their size depends on the catchment area of the sloping roof. They prevent damage to the foundations of the building and the low parts of the facades by diverting the flowing water in a controlled manner and not allowing it to pour freely from the rock directly onto the ground.

SEAMLESS GUTTERS, rollforming and installation

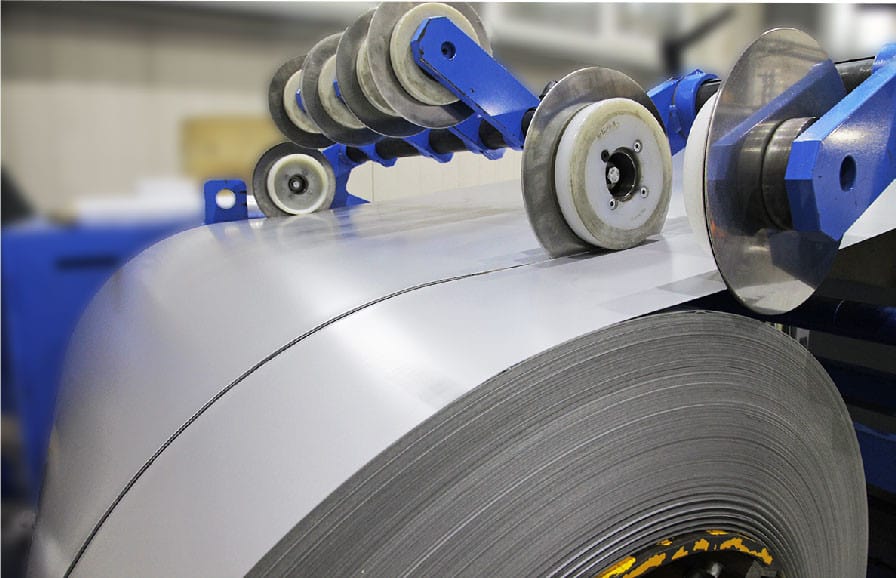

Mechanical processing in which the coiled sheet is cut lengthwise into strips of various widths by machines called slitters.

LONGITUDINAL SPLITTING

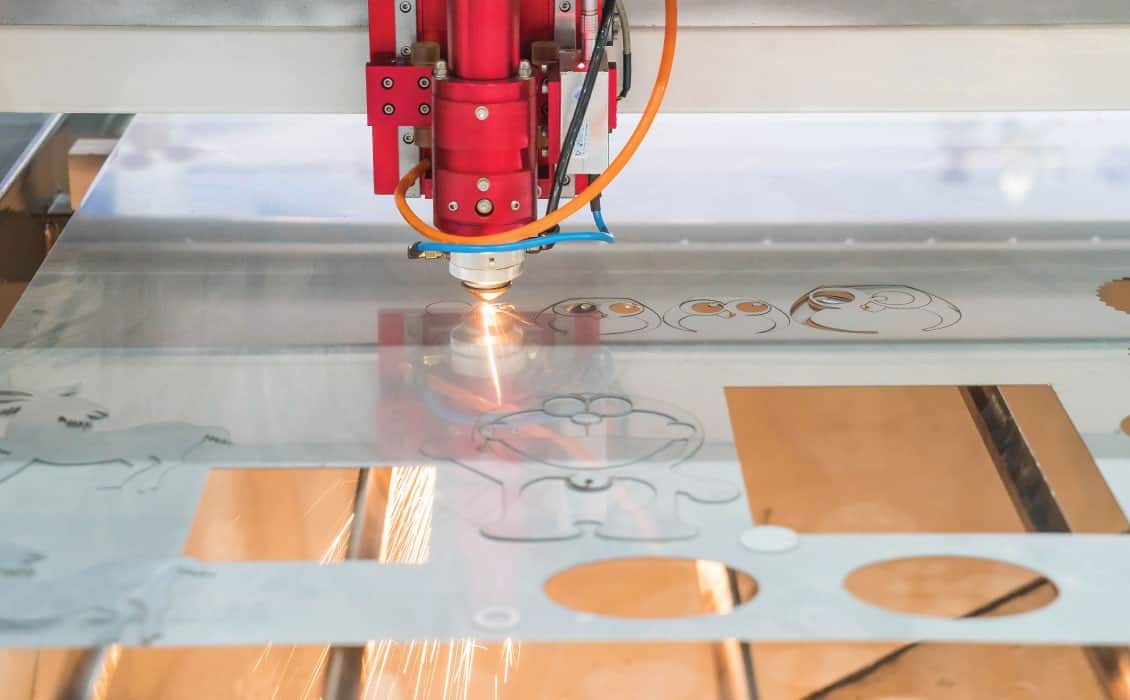

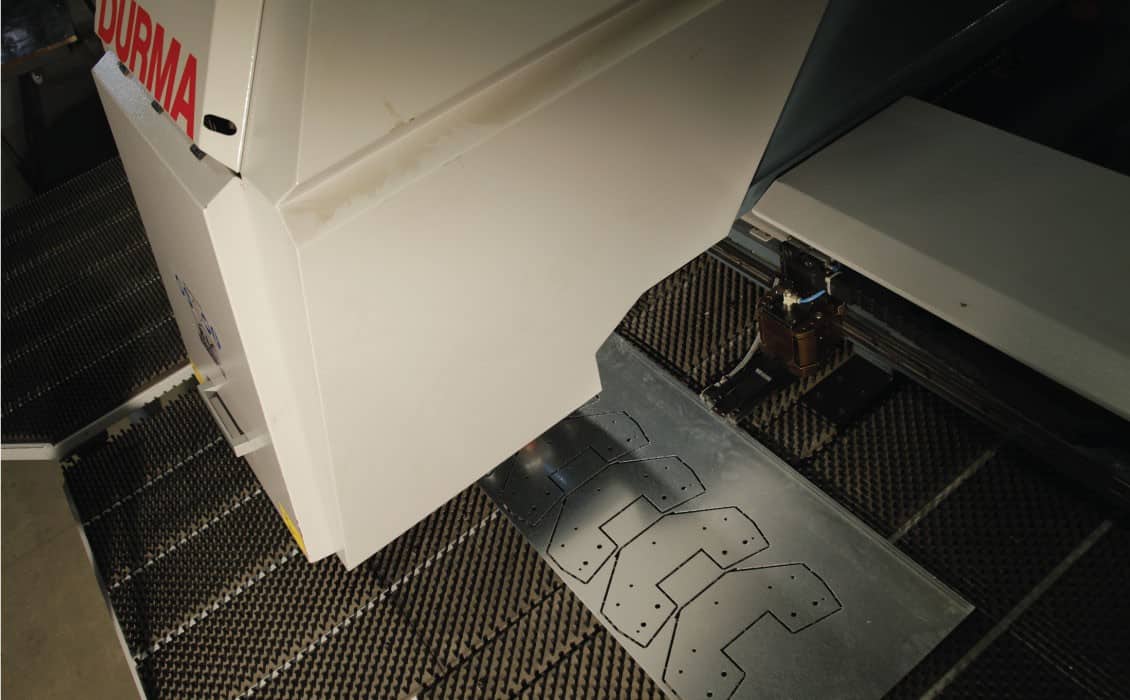

CNC cutting or contour trimming of sheet metal, as the only or the first of a series of treatments on the sheet metal.

LASER CUTTING

Punching is a mechanical sheet metal working process that most commonly creates holes in sheet metal or is used to cut complex curves that cannot be achieved by straight guillotine cutting.

PUNCHING

Bending is one of the most common sheet metal working operations and serves to give the sheet an angular shape.

BENDING

Manual or mechanized processing of blanks, details, or elements from sheet metal

TIN WORKS